Mag Core Import Direct Spark Plug Wires Review

Best Sellers

How to install an MSD 6A Digital Ignition Module on your 1979-1995 Mustang

Installation Time

iii hours

Shop Parts in this Guide

- MSD 6A Digital Ignition Module (79-95 Mustang)

Installation

Parts Included:

- 1 - MSD Ignition

- ane - Harness, PN 8860

- i - Mag Pickup

- 1 - Main Harness

- ane - Parts Bag

6AL ONLY

- iv - Vibration Mounts

- 1 - Sc rew d river

WARNING: During installation, disconnect the bombardment cables. When disconnecting the battery always remove the Negative cable beginning and install information technology last.

Note: The Carb label supplied is required to aid in passing the California Smog Cheque program. This characterization must be installed in an underhood location that is readily visible.

Annotation: If you lot're triggering an aftermarket EFI system with the Gray wire of the MSD, see folio 4 to deactivate the tach verification characteristic.

Performance AND FEATURES

DIGITAL Performance

The Digital 6A and 6AL utilize a loftier speed RISC microcontroller to control the ignition'due south output while constantly analyzing the various inputs such every bit supply voltage, trigger signals and rpm. The high speed controller can make extremely quick compensations to the output voltage, multiple spark series, timing and rpm limits while maintaining precise timing and accurate rev limiting. The circuits and controller of the MSD have been thoroughly filtered to create protection confronting Electro Magnetic Interference (EMI).

CAPACITIVE Discharge

The Digital 6A and 6AL feature a capacitive belch ignition design. The bulk of stock ignition systems are inductive ignitions. In an anterior ignition, the gyre must store and step upward the voltage to maximum forcefulness in between each firing. At higher rpm, since there is less time to charge the coil to full capacity, the voltage falls short of reaching maximum energy which results in a loss of power or superlative terminate miss.

The MSD Ignition features a capacitor which is chop-chop charged with 520 - 535 volts and stores information technology until the ignition is triggered. With the CD design, the voltage sent to the gyre positive terminal is always at full power even at high rpm.

MULTIPLE SPARKS

The MSD produces full power multiple sparks for each firing of a plug. The number of multiple sparks that occur decreases as rpm increases, all the same the spark series always lasts for twenty° of crankshaft rotation. Above 3,000 rpm at that place is simply not enough "time" to burn down the spark plug more than in one case, so there is simply ane powerful spark.

PROTECTION

The Digital 6A and 6AL accept a congenital in contrary polarity protection circuit. This will protect the ignition in the outcome of wrong connections.

LED INDICATOR

There is an LED that monitors the status of the Ignition. When the central is turned On, without starting the engine, the LED will momentarily turn on so turn off. When running, the LED will wink with each trigger signal which will make it announced to be on steady as rpm increases.

Note: Solid Core spark plug wires cannot be used with an MSD Ignition.

Note: Exercise non use digital or dial back timing lights.

REV LIMITER

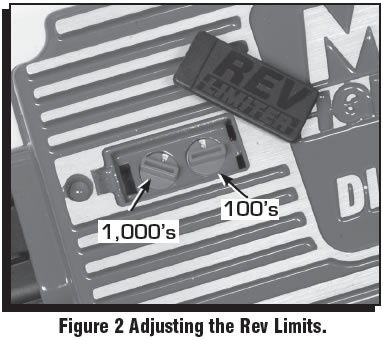

The Digital 6AL features a built-in Soft Touch on Rev Control that provides a smooth and accurate rev limit by dropping the spark to individual cylinders. The Soft Touch on produces a load-complimentary rev limit that is within 1% of the selected rpm.The rpm limit is adjusted in 100 rpm increments with the sealed rotary switches under the black comprehend on top of the 6AL.

CYLINDER SELECT

The MSD is programmed at the manufactory for employ on viii-cylinder engines. If you are installing it to a unlike engine you will have to plan the Ignition. This is easily achieved through the cylinder select wire loops on the side of the ignition. Page 5 outlines setting the cylinder select.

Full general INFORMATION

BATTERY

The Digital 6A and 6AL will operate on whatsoever negative ground, 12 volt electrical system with a distributor. The MSD can be used with 16 volt batteries and can withstand a momentary 24 volts in case of jump starts. The Ignition volition deliver full voltage with a supply of 9 - 18 volts. If your application does not apply an alternator, allow at to the lowest degree 15 amp/hour for every half hour of functioning. The MSD uses near .9 Amps for every 1,000 rpm. If the engine is cranked with the aforementioned battery or other accessories such every bit an electric fuel or h2o pump are used, the amp/hour rating should be higher.

COILS

The Digital 6A and 6AL Ignition tin be used with nigh stock coils and aftermarket coils designed to replace the stock coils. The line of MSD Blaster Coils are great for street and mild racing. For extended high rpm operation the Blaster HVC, PN 8252 or HVC II, PN 8253, are recommended. For more data on recommended coils, cheque with our Client Service Section at (915) 855-7123.

TACHOMETERS

The MSD Ignition features a Gray Tach Output wire that provides a trigger betoken for tachometers, a shift light or other add-on rpm activated devices. The Tach Output wire produces a 12 volt square moving ridge indicate with a 22.5° duty bicycle.

Some vehicles with manufactory tachometers may require a Tach Adapter to operate with the MSD. For more data on Tachometers and MSD Tach Adapters, see the Tachometer Section on page six. If your GM vehicle has an in-line filter it may cause the tach to drop to naught on dispatch. If this occurs, featherbed the filter.

SPARK PLUGS AND WIRES

Spark plug wires are very important to the performance of your ignition system. A good quality, helically wound wire and proper routing are required to get the best performance from your ignition, such every bit the MSD 8.5mm Super Conductor Wire. Helically wound wires provide a good path for the spark to follow while keeping Electro Magnetic Interference (EMI) to a minimum. Excessive EMI, such as the amount that solid core wires produce, will interfere with the operation of the MSD. Solid Core spark plug wires cannot exist used with an MSD Ignition.

Routing: Correct routing of the plug wires is also important to performance. Wires should be routed away from precipitous edges and engine rut sources. If there are two wires that are next to each other in the engine'south firing gild, the wires should be routed away from each other to avert inducing a spark into the other wire. For example, in a Chevy V8, the firing order is 1-8-iv-3-half-dozen-5-vii-2. The #5 and #7 cylinders are next to each other in the engine and in the firing social club. If the voltage from the #5 wire is induced into #7 detonation could occur and cause engine damage. To add more rut protection to your plug wires, MSD offers Pro-Heat Baby-sit, PN 3411. This is a glass woven and silicone coated protective sleeve that you slide over your plug wires. For extra protection of the spark plug boots, MSD offers Pro Boot Guard, PN 3412.

Spark Plugs: Choosing the correct spark plug blueprint and oestrus range is important when trying to get the best performance possible. Since in that location are then many engine combinations and manufacturers, MSD does not recommend which plug or gap is exactly right for your application. Information technology is recommended to follow the engine builder or manufacturer'south specification for spark plugs. With that, you can and so experiment with the plug gap to obtain the best operation. The gap of the plugs tin can be opened in 0.005" increments, then tested until the best performance is obtained. MSD judges the plug gap by compression and components.

These examples are just starting points to get y'all going in the right management. Every application is different and should be tested and tuned.

Welding: If you lot are welding on your vehicle, to avoid the chance of damage, always disconnect both Heavy Power cables of the MSD (You lot should also disconnect the tach ground wire too).

Benefactor Cap and Rotor: It is recommended to install a new distributor cap and rotor when installing the MSD Ignition Control. The cap should exist clean inside and out peculiarly the terminals and rotor tip. On vehicles with smaller caps, it is possible for the air inside the cap to go electrically charged causing crossfire which can upshot in misfire. This can exist prevented by drilling a couple vent holes in the cap. The holes should be placed between the terminals, at rotor meridian and face away from the intake. If your surroundings demands it, place a small piece of screen over the pigsty to act as a filter.

MOUNTING

The MSD can exist mounted in the engine compartment as long as it is away from directly engine rut sources. It is not recommended to mountain the unit in an enclosed area such as the glove box.

When you notice a suitable location to mount the unit of measurement, brand sure the wires of the ignition achieve their connections. Also be sure that the program dials tin can be accessed. Hold the Ignition in place and marking the location of the mounting holes. Use a iii/sixteen" bit to drill holes, install the vibration mounts and mount the ignition.

Wiring

The Digital 6A and 6AL use a master wiring harness that connects to the ignition through a sealed and locked connexion.

Wire Length: All of the wires of the MSD Ignition may be shortened equally long as quality connectors are used or soldered in place. To lengthen the wires, use one size bigger gauge wire (12 gauge for the ability leads and 16 gauge for the other wires) with the proper connections. All connections must be soldered and sealed.

Grounds: A poor ground connexion can cause many frustrating problems. When a wire is specified to go to ground, it should be connected to the battery negative concluding, engine block or chassis. In that location should ever be a footing strap between the engine and the chassis. Always securely connect the basis wire to a clean, paint free metal surface.

Anchor Resistor: If your vehicle has a anchor resistor in-line with the gyre wiring, it is recommended to featherbed it.

Routing Wires: The MSD wires should be routed away from direct heat sources such as exhaust manifolds and headers and whatsoever sharp edges. The trigger wires should be routed separate from the other wires and spark plug wires. It is all-time if they are routed along a ground aeroplane such as the block or firewall which creates an electrical shield. The magnetic pickup wires should always be routed separately and should be twisted together to help reduce inapplicable interference.

PROGRAMMING

CYLINDER SELECT

The MSD is programmed for functioning on eight-cylinder engines. If installing the Ignition on a unlike style engine, the number of cylinders will demand to be selected by cutting the cylinder select wire loops as shown in Figure 1.

REV LIMITER

The rev limiter can be set up from ii,000 to 11,000 rpm. To adjust the rev limiter of the Digital 6AL, remove the blackness cover next to the LED by prying up with the supplied screwdriver. The dial on the left is for 1,000 rpm increments, on the right is for 100 rpm increments.

For a rev limiter in the 10,000 range, prepare the dials every bit they would be for any other RPM merely the left punch will apply '0'. To set the rev limiter to 11,000 rpm, put the left dial to '1' and the right dial to '0'. Setting both rotary dials to '1' will activate a special function explained below.

Notation: The engine can exist running as you brand adjustments to the rev limiter function.

REV LIMITER VERIFICATION

The MSD Digital 6AL has an optional built in Rev Limiter Verification characteristic. When the cardinal is in the On position (non cranking or running), an rpm betoken is sent to the tachometer to verify the unit of measurement's rev limit setting. With this role users tin be sure of their rev limit settings before each drive.

Note: It is important to note that this characteristic should non be used with EFI systems. When activated, an rpm indicate is sent to the tachometer. With an aftermarket EFI system, this could activate the injectors causing a flooding situation.

Enable Rev Limit Verification

one. Ground the Gray tach output wire.

ii. Turn on power to the ignition without starting the engine.

three. Hold the Gray tach output wire to ground for seven seconds. (AT Least five seconds.)

4. Release the wire from ground before 10 seconds accept passed.

v. To confirm the process has worked, cycle turn the key On. The tachometer should sweep to the rpm limit assail the ignition.

As presently as this process is complete the feature will be activated. The Digital 6AL uses the blood-red LED to assist indicate when an adequate amount of time has passed to release the Gray tach wire. The LED will turn on after the wire has been grounded for five seconds and will turn off at the 10 second mark. To deactivate the feature once more, echo the same process.

Playback Tach: If y'all use a playback tach, be sure to check the high rpm value prior to turning the key to the On position. When the key is in the On position, the rev limit will be displayed and may override the tach memory.

CONNECTING THE DIGITAL 6AL WITH THE MSD Power Grid SYSTEM CONTROLLER, PN 7730

A wiring diagram to connect the MSD Power Filigree System Controller to a 6AL tin can be found in the instructions for the Organisation Controller, PN 7730. A special rev limit must be selected when connecting to the Ability Grid. This setting is (one / 1), meaning to put both dials on 1. With the Digital 6AL's Rev Limit Rotary Dials both set to one, the box programming will alter to accept the Ability Filigree. Note: Under no other conditions should the rotary dials be set to (one / 1); this could crusade severe issued with how the box reads the input signal. Similarly, using the System Controller when the 6AL is not fix to ane / 1 will cause problems that could result in engine damage.

Annotation: The 6A, PN 6201, is not compatible with the Power Grid Controller.

PRESTART CHECK LIST

- The just wires connected to the whorl terminals are the MSD Orange to coil positive and Black to coil negative.

- The small Red wire of the MSD is connected to a switched 12 volt source.

- The MSD power leads are connected directly to the battery positive and negative terminals.

- The battery is connected and fully charged if not using an alternator.

- The engine is equipped with at to the lowest degree 1 ground strap to the chassis.

- If y'all are installing on a 4 or half dozen-cylinder engine, confirm the programming loops have been modified, encounter page v.

THEFT DETERRENT

The MSD provides the opportunity to easily install a theft deterrent kill switch (Effigy iii). When using the WHITE wire to trigger the MSD, install a switch across the magnetic pickup VIOLET wire to ground. When the VIOLET wire is grounded, the vehicle will crank simply non commencement.

Magnetic Pickup Trigger

When using the mag pickup to trigger the MSD, install a switch to the WHITE wire and the other side to ground. When the WHITE wire is grounded, the vehicle will creepo but volition non start.

TROUBLESHOOTING

Every MSD Ignition undergoes numerous quality command checks including a four 60 minutes burn-in test. If you experience a problem with your MSD, our research has shown that the majority of problems are due to improper installation or poor connections.

The Troubleshooting section has several checks and tests you tin can perform to ensure proper installation and operation of the MSD. If you have any questions concerning your MSD, phone call our Customer Support Department at (915) 855-7123, 7 - 5 mount time.

LED

The LED will flash for every trigger signal from the benefactor or crank trigger. You lot can take reward of this when statically setting the timing when faux triggering the box to troubleshoot. Also, when the engine is non running, the LED will be On when the key is in the On position.

TACH/FUEL ADAPTERS

If your tachometer does not operate correctly or if you feel a no-run situation with your foreign vehicle you probably demand an MSD Tach Adapter. The chart in Figure four lists mutual tachometers and if an Adapter is necessary.

NO-RUN ON FOREIGN VEHICLES

Some strange vehicles with fuel injection systems may require an MSD Tach/Fuel Injection Adapter to run with an MSD vi Series Ignition. This is considering many of these systems use the same trigger source to operate the MSD, the tachometer and the fuel injection. This results in a voltage signal that is likewise low to accurately trigger the fuel injection. To ready this, an MSD Tach Adapter, PN 8910, will remedy the problem on the majority of vehicles. If the PN 8910 does not set up the problem, the PN 8910-EIS will be required.

Note: Toyotas and Ford Probes volition require the PN 8910-EIS Adapter.

INOPERATIVE TACHOMETERS

If your tachometer fails to operate with the MSD installed yous may demand an MSD Tach Adapter. Before getting an Adapter, try connecting your tachometer trigger wire to the Gray tach wire of the MSD. This output produces a 12 volt, foursquare wave (see page ii). If the tach still does not operate, you will need a Tach Adapter. There are ii Tach Adapters:

PN 8920: If you are using the Magnetic Pickup connector (Light-green and Violet wires) to trigger the MSD, you will need the PN 8920.

PN 8910: If your tachometer was triggered from the curlicue negative terminal (voltage trigger) and you lot are using the White wire to trigger the MSD yous will need the PN 8910.

BALLAST RESISTOR

If you take a electric current trigger tach (originally coil positive) and use the White wire of the MSD, yous can purchase a Chrysler Dual Ballast Resistor (used from 1973 - 1976) and wire information technology as shown in Figure five.

Note: On the list above, the trigger wire on tachometers that are marked NONE may exist connected to the Greyness Tach Output Wire on the MSD 6AL Ignition.

ENGINE RUN-ON

If your engine continues to run even when the ignition is turned Off you are experiencing engine Run-On. This unremarkably merely occurs on older vehicles with an external voltage regulator. Because the MSD receives power directlyfrom the battery, it does non crave much current to keepthe unit energized. If you are experiencing run-on, it is due to a small corporeality of voltage going through the charging lamp indicator and feeding the minor Red wire fifty-fifty if the key is turned off.

Early on Ford and GM: To solve the Run-On problem, a Diode is supplied with the MSD in the parts handbag. By installing this Diode in-line of the wire that goes to the Charging indicator, the voltage is kept from entering the MSD. Figure half dozen shows the proper installation for early Ford and GM vehicles.

Note: Diodes are used to allow voltage to flow but one way. Make certain the Diode is installed facing the proper management (equally shown in Effigy 6).

Ford: Install the Diode in-line to the wire going to the "ane" concluding.

GM: Install the Diode in-line to the wire going to concluding #four.

GM: 1973 - 1983 with Delcotron Alternators.

GM: Delcotron Alternators apply an internal voltage regulator. Install the Diode in-line on the smallest wire exiting the alternator (Figure seven). It is commonly a Brown wire.

MISSES AND INTERMITTENT Problems

Feel at the races has shown that if your engine is experiencing a miss or hesitation at higher rpm, it is usually non direct ignition. Most likely causes include faulty wiring, a coil or plug wire failure, arcing from the cap or boot plug to ground or spark ionization within the cap. Several items to inspect are:

- Always audit the plug wires at the cap and at the plug for a tight connection and visually inspect for cuts, abrasions or burns.

- Audit the Primary Curl Wire connections. Considering the MSD is a Capacitive Discharge ignition and it receives a direct 12 volt source from the battery, in that location will not be any voltage at the Coil Positive ( ) concluding even with the key turned On. During cranking or while the engine is running, very high voltage will exist present and no exam equipment should exist continued.

Alert: Do not touch the curl terminals during cranking or while the engine is running.

- Brand sure that the battery is fully charged and the connections are clean and tight. If you lot are non running an alternator this is an imperative cheque. If the battery voltage falls below nine volts during a race, the MSD output voltage will drib and the current describe will increase.

- Is the engine running lean? Audit the spark plugs and complete fuel system.

- Inspect all wiring connections for corrosion or impairment. Remember to ever utilise proper connections followed past soldering and seal the connections completely.

If everything checks positive, use the following procedure to examination the ignition for spark. MSD also offers an Ignition Tester, PN 8998 or PN 8996. This tool allows yous to bank check your complete ignition organization while it is in the car equally well as the operation of rpm limits, activated switches and shift lights.

CHECKING FOR SPARK

If triggering the ignition with the White wire:

1. Brand sure the ignition switch is in the "Off" position.

two. Remove the gyre wire from the distributor cap and set the concluding approximately 1/ii" from ground.

three. Disconnect the MSD White trigger wire from the distributor.

4. Turn the ignition to the On position. Practise non crank the engine.

5. Tap the White wire to ground several times. Each time you pull the wire from ground, a spark should leap from the roll wire to ground. If spark is present, the ignition is working properly. If in that location is no spark skip to pace 6.

If triggering with the Magnetic Pickup:

ane. Make sure the ignition switch is in the "Off" position.

2. Remove the curlicue wire from the benefactor cap and set the final approximately 1/ii" from ground.

3. Disconnect the MSD magnetic pickup wires from the distributor.

four. Turn the ignition to the On position. Practise not crank the engine.

5. With a small-scale jumper wire, brusque the MSD's Green and Violet magnetic pickup wires together several times. Each time you suspension this brusque, a spark should jump from the roll wire to basis. If spark is nowadays, the ignition is working properly. If at that place is no spark skip to step 6.

6. If there is no spark:

A. Audit all of the wiring.

B. Substitute another gyre and repeat the examination. If in that location is now spark, the coil is at fault.

C. If at that place is yet no spark, check to brand sure there are 12 volts on the pocket-size Cherry-red wire from the MSD when the key is in the On position. If 12 volts are not present, find some other switched 12 volt source and echo the test.

D. If, after post-obit the test procedures and inspecting all of the wiring, in that location is even so no spark, the MSD Ignition is in need of repair. Meet the Warranty and Service section for information.

The following wiring diagrams illustrate numerous installations on unlike vehicles and applications. If you experience difficulties when installing your MSD, contact our Customer Support Department at (915) 855-7123 (vii - v Mountain time) or e-mail us at: [electronic mail protected]

Best Sellers

hartsocktrainsomill1963.blogspot.com

Source: https://www.americanmuscle.com/msd-6a-digital-ignition-7995-install.html

0 Response to "Mag Core Import Direct Spark Plug Wires Review"

Post a Comment